Back to top

Versatile Applications in Infrastructure

MS Channels serve as vital structural elements across various industries including construction, industrial sheds, bridges, and fabrication works. Their adaptability allows them to be used in purlins, frameworks, and as a core component in heavy-duty and light-weight structures, providing structural support and stability wherever needed.

Customizable Dimensions and Superior Material Quality

Supplied according to IS standards, MS Channels come in a range of sectional dimensions, from standard sizes such as 75x40 mm, 100x50 mm, and 125x65 mm, to tailor-made sizes and lengths according to client specifications. Made from mild steel, they offer an excellent combination of strength, ductility, and workability.

Long-Lasting Performance and Finishing Options

To cater to diverse project requirements, MS Channels are available with options for anti-corrosive coatings upon request, ensuring enhanced resistance in challenging environments. The hot-rolled, mild steel finish ensures durability, while their straight, square edges guarantee precise fitment during installation.

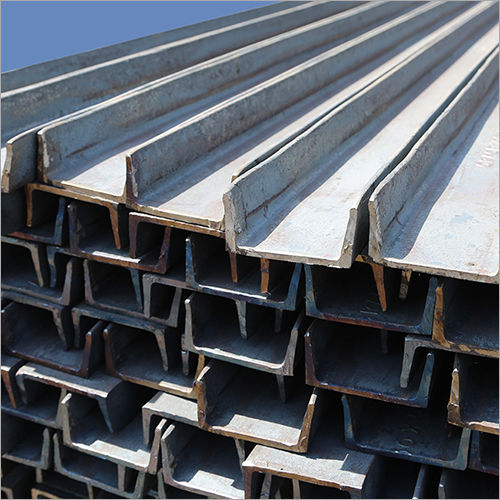

MS Channels

42.00 - 60.00 INR

Product Details:

- Type MS Channel

- Material Mild Steel (MS)

- Size Available in standard sizes such as 75x40 mm, 100x50 mm, 125x65 mm, and custom sizes on request

- Weight Varies with size, typically ranges from 7.14 kg/m to 20.9 kg/m

- Length 6 meter, 9 meter, or as per requirement

- Thickness 4 mm to 12 mm

- Color Black or as per requirement

- Click to View more

X

MS Channels Price And Quantity

- 42.00 - 60.00 INR

- 1000 Kilograms

MS Channels Product Specifications

- 6 meter, 9 meter, or as per requirement

- Hot Rolled, Mild Steel finish

- Black or as per requirement

- MS Channel

- 4 mm to 12 mm

- Mild Steel (MS)

- Available in standard sizes such as 75x40 mm, 100x50 mm, 125x65 mm, and custom sizes on request

- IS 2062, E250, E350 or as specified

- Varies with size, typically ranges from 7.14 kg/m to 20.9 kg/m

MS Channels Trade Information

- 400 Kilograms mt Per Day

- 1 Week

Product Description

We are famous amongst our customers as a trustworthy organization engaged in supplying our clients with MS Channels. These channels find use in fabrication of steel structure, in bridges, for automobile chassis and others. The channels allow easy work-ability including forming, cutting, welding and machining support. Clients can avail our channels in hot dipped galvanized, pre-galvanized, coated and other finishes as per the requirements. We source these channels from the trusted and reputed vendors of the market. MS Channels are also used in EOT cranes, shipbuilding, factory sheds, and conveyors.

Versatile Applications in Infrastructure

MS Channels serve as vital structural elements across various industries including construction, industrial sheds, bridges, and fabrication works. Their adaptability allows them to be used in purlins, frameworks, and as a core component in heavy-duty and light-weight structures, providing structural support and stability wherever needed.

Customizable Dimensions and Superior Material Quality

Supplied according to IS standards, MS Channels come in a range of sectional dimensions, from standard sizes such as 75x40 mm, 100x50 mm, and 125x65 mm, to tailor-made sizes and lengths according to client specifications. Made from mild steel, they offer an excellent combination of strength, ductility, and workability.

Long-Lasting Performance and Finishing Options

To cater to diverse project requirements, MS Channels are available with options for anti-corrosive coatings upon request, ensuring enhanced resistance in challenging environments. The hot-rolled, mild steel finish ensures durability, while their straight, square edges guarantee precise fitment during installation.

FAQs of MS Channels:

Q: How are the dimensions of MS Channels determined for different applications?

A: The dimensions of MS Channels, such as depth, width, and flange thickness, are based on applicable IS standards and specific project requirements. Standard sizes include 75x40 mm, 100x50 mm, and 125x65 mm, but custom dimensions can be provided according to the type and load-bearing needs of your application.Q: What are the key benefits of using MS Channels in construction and fabrication?

A: MS Channels offer high strength-to-weight ratio, excellent workability, and versatility, making them ideal for structural frameworks, bridges, industrial sheds, and purlins. Their reliable performance, availability in various sizes, and custom options provide optimal solutions for diverse infrastructure demands.Q: When should anti-corrosive coating be requested for MS Channels?

A: It is advisable to request anti-corrosive coatings when MS Channels will be exposed to humid, corrosive, or harsh environments. This optional enhancement significantly improves resistance to rust and extends the service life of the material in outdoor or industrial settings.Q: Where can MS Channels be sourced in India, and what is the typical process of procurement?

A: MS Channels can be sourced through reputed distributors, suppliers, traders, or wholesalers across India. The procurement process typically involves specifying the required dimensions, grade, quantity (MOQ as per supplier policy), and any finishing or coating preferences. Suppliers will provide quotations, and delivery is arranged as per agreement.Q: What is the advantage of custom length and bundled packing for MS Channels?

A: Custom lengths allow for efficient installation, minimizing waste and additional cutting on-site. Bundled packing ensures safer handling, storage, and transportation of MS Channels, especially for large-scale orders, while loose packing is also available for specific needs.Q: How does the tensile strength of MS Channels contribute to structural safety?

A: With tensile strength ranging from approximately 410 to 560 MPa, MS Channels provide robust load-bearing capacity, helping ensure structural integrity and longevity in demanding construction and industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'MS Channels' category

|

KAMRUP STEEL TRADERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |