Back to top

Premium Mild Steel Construction

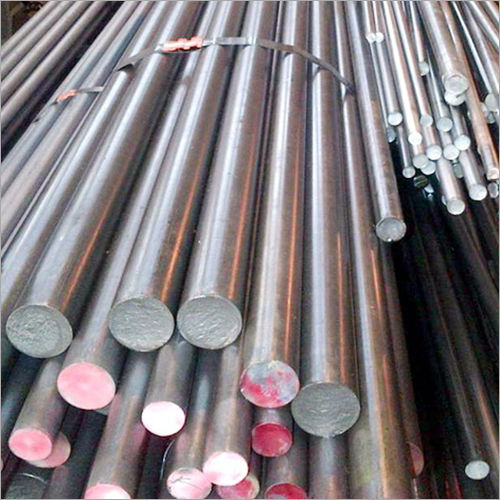

These MS Solid Round Bars are engineered to deliver robust performance across a range of applications, including construction and structural projects. Precisely manufactured to tolerances h9/h11, they ensure reliability and meet stringent industry standards. Each bar is available in multiple grades, finished in bright or black for enhanced versatility.

Flexible Sizing & Standards

Sizes from 10 mm to 150 mm in diameter offer adaptability for diverse demands. Choose from internationally recognized standards such as IS, ASTM, BS, and DIN to match specific project requirements. Standard lengths of 6 meters make logistics and fabrication seamless for distributors, suppliers, and traders throughout India.

MS Solid Round Bars

42.00 - 60.00 INR

Product Details:

- Type Solid Round Bar

- Material Mild Steel (MS)

- Size 10 mm to 150 mm (Diameter)

- Weight Varying as per size (e.g. 0.62 kg/m for 10 mm)

- Length 6 Meter (Standard)

- Thickness As per diameter, 10 mm to 150 mm

- Color Gray

- Click to View more

X

MS Solid Round Bars Price And Quantity

- 42.00 - 60.00 INR

- 1000 Kilograms

MS Solid Round Bars Product Specifications

- As per diameter, 10 mm to 150 mm

- Solid Round Bar

- Mild Steel (MS)

- 6 Meter (Standard)

- Varying as per size (e.g. 0.62 kg/m for 10 mm)

- IS 2062 / ASTM A36 / EN8 / EN9

- 10 mm to 150 mm (Diameter)

- Bright / Black

- Gray

MS Solid Round Bars Trade Information

- 400 Kilograms mt Per Day

- 1 Week

Product Description

We are emerging as one of the fastest growing companies engaged in supplying MS Solid Round Bars. These bars are known for their tensile strength, high resistance to rust, and high fabrication ability. They are a versatile choice for applications where durable support and corrosion resistance are required. These can be used for making fittings, screws, washers, nuts, mounting, and ornamental work. MS Solid Round Bars have a fair resistance to thermal and electrical conductivity. These round bars are available for clients in standard dimensions to meet their exact needs. We offer these bars at reasonable prices.

Premium Mild Steel Construction

These MS Solid Round Bars are engineered to deliver robust performance across a range of applications, including construction and structural projects. Precisely manufactured to tolerances h9/h11, they ensure reliability and meet stringent industry standards. Each bar is available in multiple grades, finished in bright or black for enhanced versatility.

Flexible Sizing & Standards

Sizes from 10 mm to 150 mm in diameter offer adaptability for diverse demands. Choose from internationally recognized standards such as IS, ASTM, BS, and DIN to match specific project requirements. Standard lengths of 6 meters make logistics and fabrication seamless for distributors, suppliers, and traders throughout India.

FAQs of MS Solid Round Bars:

Q: How can MS Solid Round Bars be used in construction and industrial engineering?

A: MS Solid Round Bars are commonly employed in construction, fabrication, industrial engineering, and structural work due to their excellent machinability and high tensile and yield strength. They serve as crucial components for frameworks, reinforcements, machinery, and support structures.Q: What are the key benefits of using MS Solid Round Bars with tolerance h9/h11?

A: The h9/h11 tolerance ensures precise dimensions, which is vital for consistency in assembly and manufacturing processes. This results in easier fitting, better load distribution, and more reliable structural performance.Q: When should the bars be painted or coated before use?

A: Since these MS Solid Round Bars have low corrosion resistance, painting or coating is recommended before installation in environments exposed to moisture, chemicals, or external weather. For internal or covered applications, uncoated use may suffice, but protective treatment extends product life.Q: Where are MS Solid Round Bars most suitable for installation?

A: They are best suited for internal or covered areas, or where proper coating or painting can be ensured. Applications include indoor construction, fabrication workshops, machinery manufacturing, and structural frameworks that are shielded from corrosive elements.Q: What process is followed for ensuring the quality of MS Solid Round Bars?

A: Quality assurance involves meeting industry standards (IS 2062, ASTM A36, EN8, EN9), checking machinability, tensile and yield strength, and surface finish (bright/black). Bars undergo rigorous dimensional testing to comply with set tolerance levels (h9/h11) as per client specifications.Q: How does the choice of grade affect the usage of MS Solid Round Bars?

A: Different grades such as IS 2062, ASTM A36, EN8, and EN9 provide varying mechanical properties and hardness. Selecting the appropriate grade ensures optimal performance for specific uses, such as higher strength requirements or improved machinability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Mild Steel Round Bars' category

|

KAMRUP STEEL TRADERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |